Limble's Modern CMMS Maintenance Software

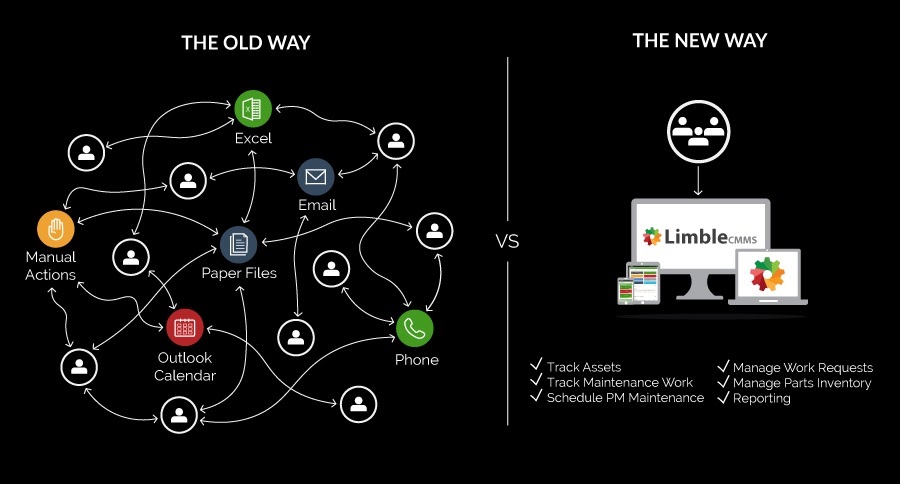

Sick of using the old phone and email system that result in LOST tickets, constant daily interruptions and duplicated work?

Limble CMMS's Work Request System allows anyone you authorize to submit a problem to your maintenance department by simply scanning a QR (bar code) code or visiting a URL and typing in their request.

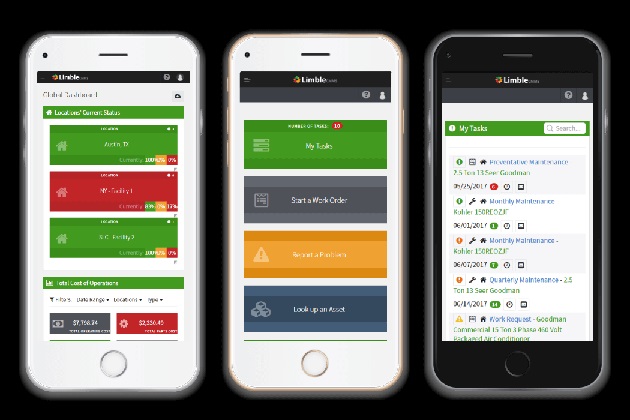

Through the use of our Android and IOS mobile apps, our clients experience better organization, communication, accountability and productivity by up to 30% throughout their entire maintenance team.

From their handheld device anyone on your maintenance team can:

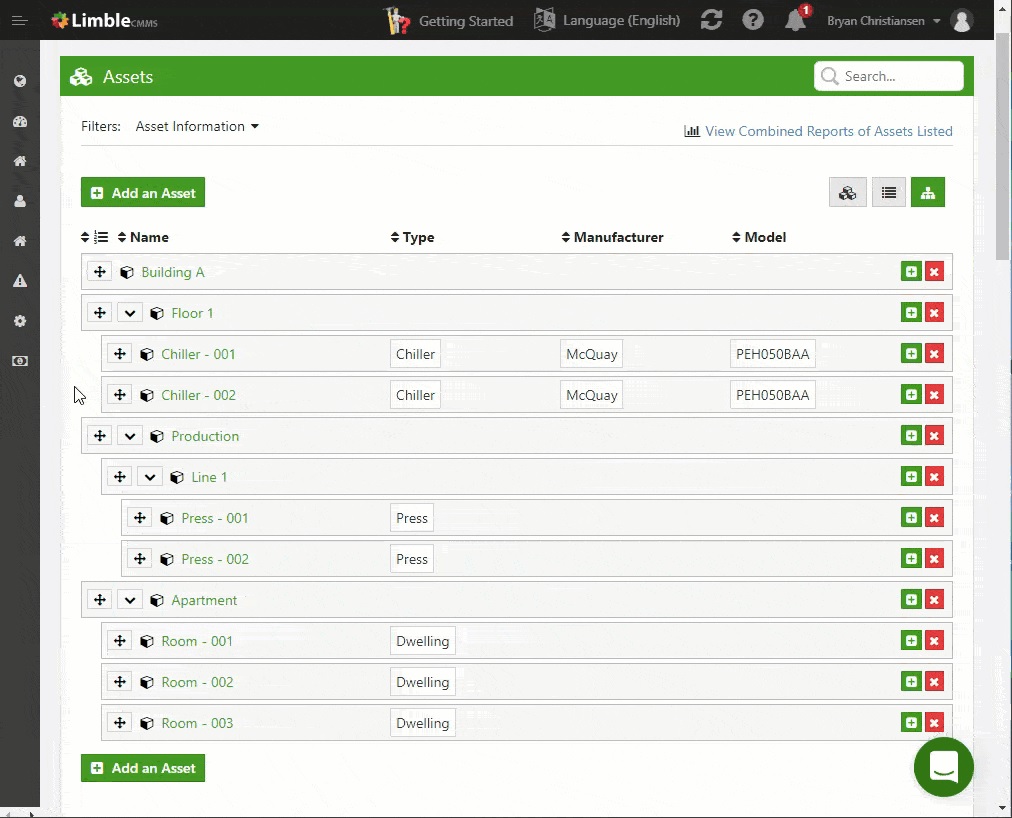

Frustrated with trying to organize the chaotic mess of company's equipment, wondering if the equipment has been properly taken care of, not knowing what they cost to maintain and all the other headaches that come with managing assets?

Limble CMMS's Enterprise Asset Management module can be used for anywhere between 10 to 100,000 Assets, allowing you to track exactly what you want, the way you want to, in an easy-to-use and searchable tree structure.

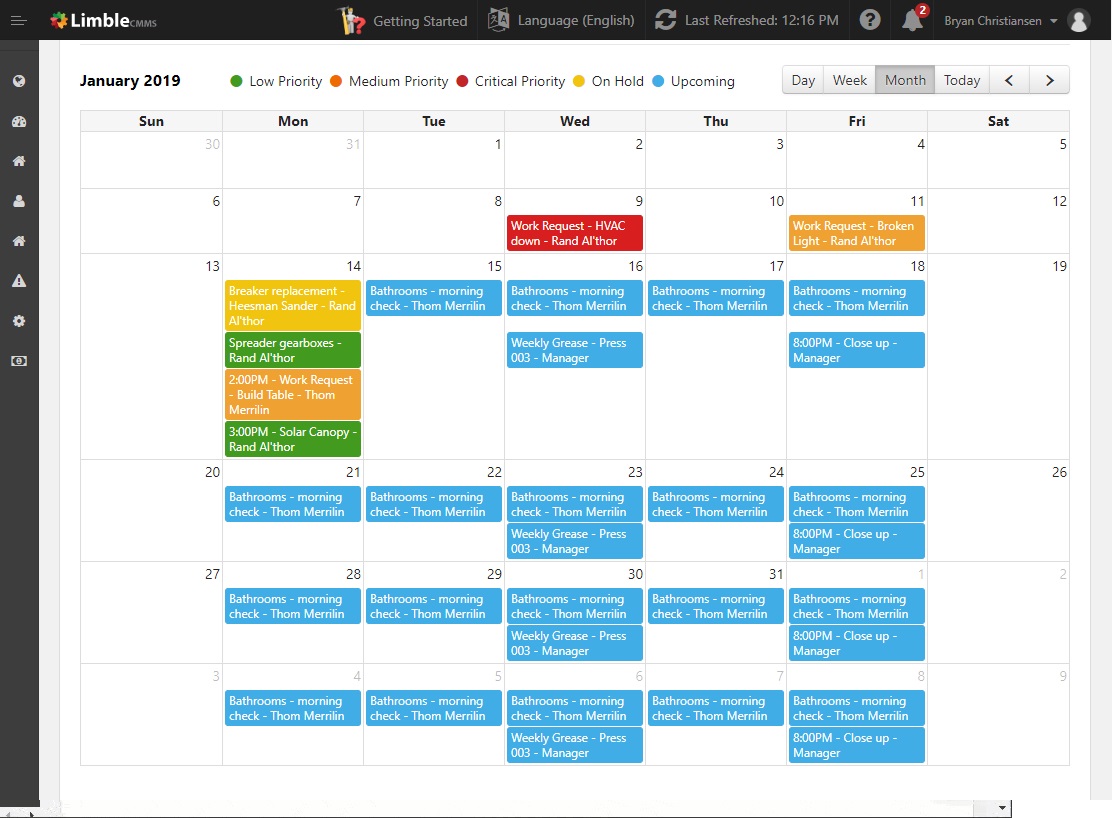

Stop wasting precious hours manually distributing PM checklists and following up with your team to make sure the work is done.

Limble allows you to easily automate PM scheduling so the right work is automatically delivered at the right time to the right technician for the right Asset.

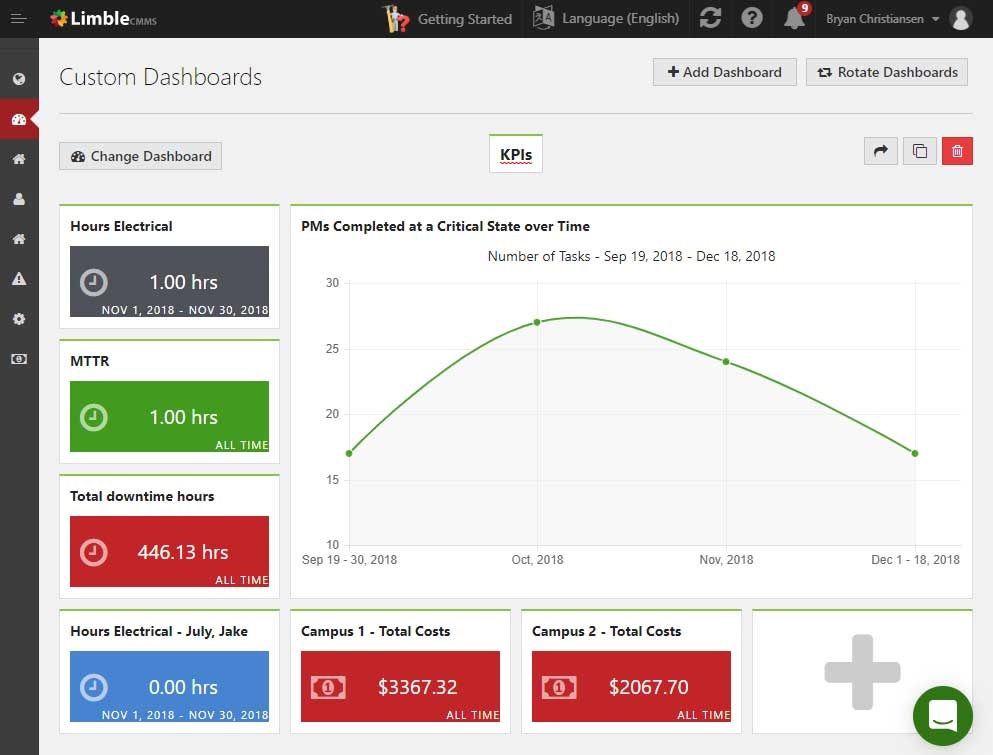

Let's face it, the first step to improving your operations is to know the good, the bad and the ugly.

With Limble's Custom Dashboards you can finally start to understand that nefarious "black hole of maintenance" and begin putting data-backed plans into action, resulting in reduced labor costs, decreased downtime and more.

With Limble's Custom Dashboards you'll get to ...

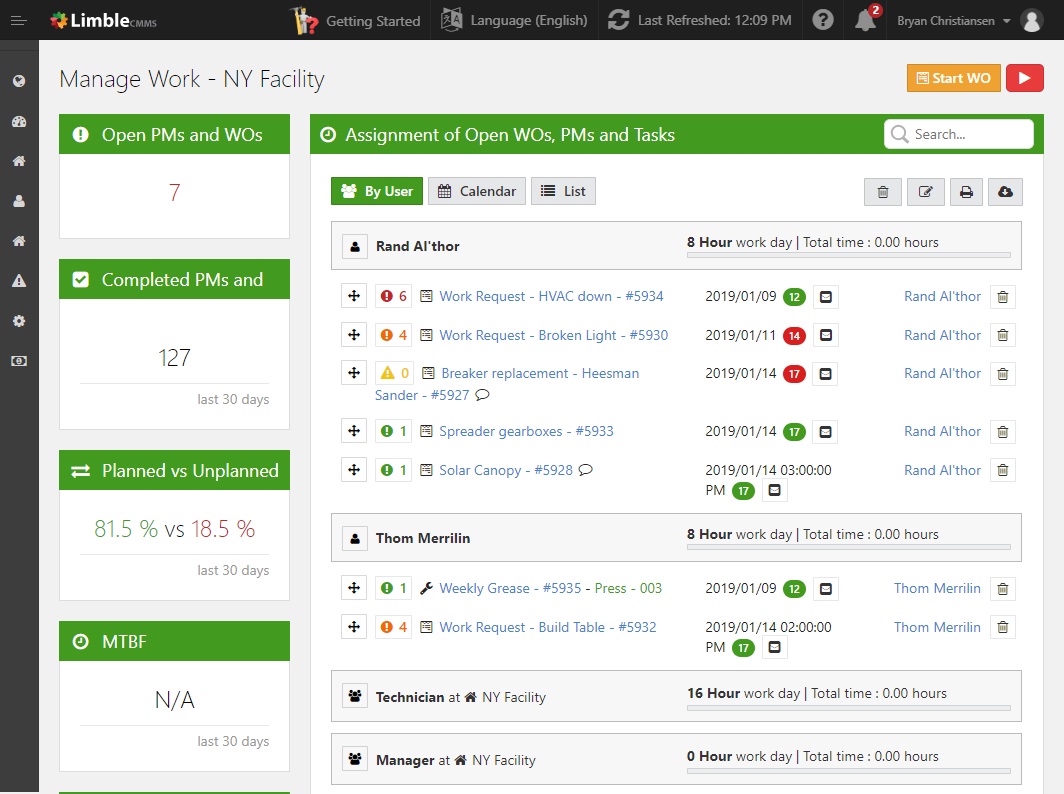

Sick of the reams of paperwork and lost Work Orders? All of those lost items directly affect the bottom line and your reputation.

With Limble you can easily and quickly organize all of your Work Orders, PMs and other Tasks throughout your team in a centralized database that can be accessed anywhere on any device.

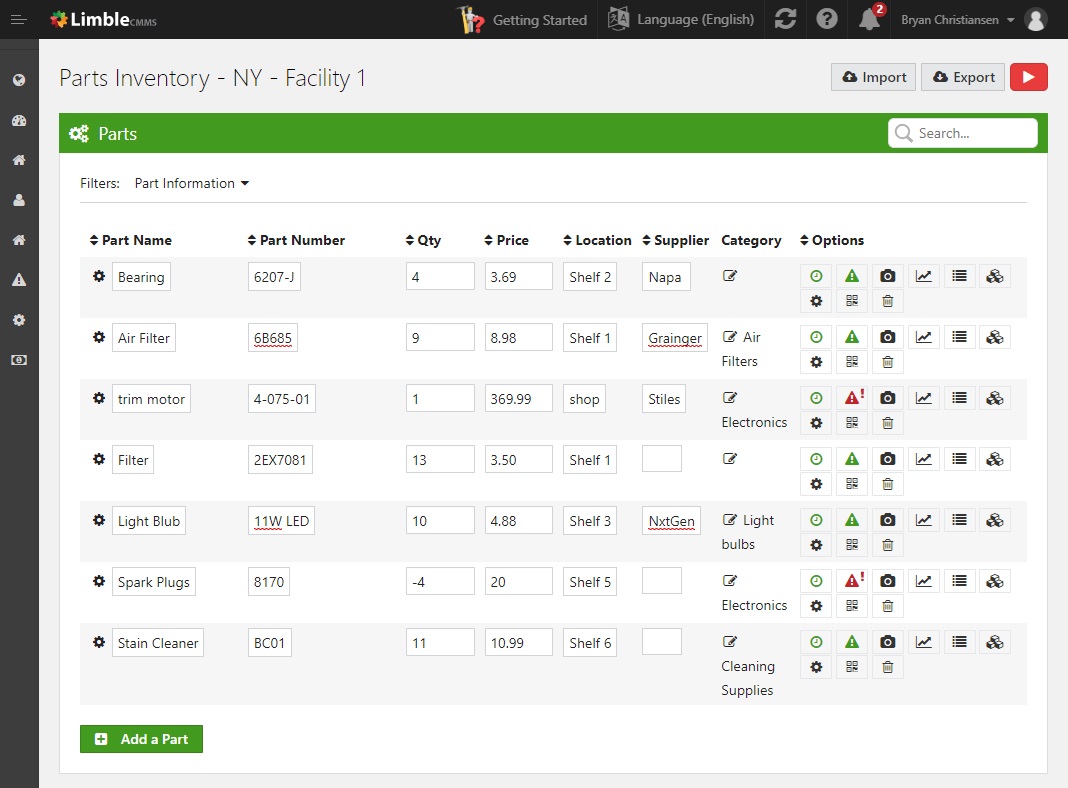

Not sure what parts you have in stock or where they are being used? Don't know when your parts will run out or if your technicians will have the necessary parts to do their jobs?

We designed Limble's parts management to solve those problems and more:

Q: What does CMMS stand for?

A: CMMS stands for computerized maintenance management system or computerized maintenance management software, which simply means software that is designed to help you organize, plan, track and simplify your maintenance operations.

Q: What is a CMMS used for?

A: CMMS software can be used for many things; however, it is mostly used to help you organize, plan, track and simplify your maintenance operations. This is done by facilitating the tracking of Work Orders (WOs), scheduling of preventive maintenance (PMs), receiving external work requests, managing assets, manage part inventories and generating maintenance reports.

Q: How does a CMMS help Work Orders?

A: Work Order Management can become a complicated and unorganized undertaking without the right tools. A CMMS system helps you organize and track all of your Work Orders. You can see what work needs to be done, who needs to do it, how much time it took, how many parts were used, what invoices were involved and much more. Additionally, Work Orders can be tied to specific assets, creating data that is valuable when making critical business decisions such as if an asset should be replaced or allowed to run for another year.

Q: How does a CMMS help Preventative Maintenance?

A: The benefits of Preventative Maintenance are well-known facts: longer equipment life, less energy consumption, fewer production delays, and much more. However, getting a PM program established and in place can be a daunting task. A CMMS maintenance software will help you perform this by creating a platform where you can automatically schedule work months or even years into the future. The planned work is automatically generated for the right person, and reminders are automatically sent out. Additionally, all of the PMs are tracked so you know how much time they are taking and if they are being done on time.

Q: How does a CMMS help Work Requests?

A: Without CMMS programs, Work Requests happen in a very manual and time intensive way, and usually do not have a procedure for requester follow up. Phone calls or emails to the maintenance team take up precious time and effort that is better spent elsewhere. A CMMS system automates this process by allowing anyone within your organization to submit a Work Request, which is automatically delivered to the right maintenance team member. When the work is completed, the person who requested the work receives notice that it has been completed, along with completion notes.

Q: How does a CMMS help track Asset History?

A: CMMS systems enable you to track anything you deem valuable for a given asset. You can track Work Orders, Preventative Maintenance, Predictive Maintenance, labor costs, parts costs and more. Additionally, you can attach manuals, PDFs, serial numbers and any other piece of information you need recorded. This establishes an extensive repository of information for each asset, arming with you with necessary information needed for critical business decisions.

Q: How does a CMMS help manage Spare Part inventories?

A: CMMS systems allow you to keep a running inventory of critical parts or tools that are needed for your maintenance operations. Parts are integrated with work orders and preventive maintenance so that your maintenance technicians can easily see if you have the right parts in stock before performing the work. Additionally, you can view how many parts were used within a given time, how many you may need in the upcoming year, and much more.

Q: How does a CMMS help with Reporting?

A: One of the most powerful aspects of a CMMS is putting your data to work for you. Now that everything is being tracked, you can pull reports that answer questions you were never able to answer before. Is the right maintenance work being done? What asset is costing me the most? Where is my maintenance team's time being spent? Is maintenance work done on time? What asset is breaking down the most? Which of my maintenance team members is performing best? CMMS reports allow you to answer all of these questions and more.

Q: Where can a CMMS be installed?

A: CMMS systems can be installed either as an on-premise solution or as a cloud or SaaS-based solution. On-premise installations require you to install the software at your office on your servers. They are maintained by your IT staff, and often require a large setup fee and ongoing server maintenance costs. Cloud or SaaS-based solutions are set up on your CMMS vendor's systems and do not require you to configure servers or perform server maintenance. A good CMMS vendor will have advanced security and storage features, including frequent data backups. Both types of installations have pros and cons, and it is best to talk with a CMMS specialist to see what best fits your needs and budget.

Q: How long does a CMMS implementation take?

A: This can widely vary based on many factors. How large is your business? How many features or modules are you trying to implement? Do you have team buy-in not only from your maintenance team, but from other managers? How difficult to use is the CMMS software you are choosing? How much time can you put into the implementation? Answering these questions should give you a better understanding of the time a CMMS implementation will take. At Limble CMMS, our average customer is set up within minutes and successfully implemented within a matter of weeks.

Q: How often is CMMS software updated?

A: This will depend on the type of installation you choose. Cloud or SaaS-based CMMS software is often updated on a daily basis with no hassle on your part. On-premise updates involve you or your IT team and are often updated anywhere from every 3 months to once a year.

Q: Where is the CMMS data stored?

A: This also depends on the type of installation you choose. Cloud or SaaS-based CMMS software will have the data stored on the CMMS software provider's servers. On-premise will store the CMMS data on your server at your location.

Q: What industries benefit from a CMMS system?

A: Many industries can benefit from a CMMS, including Manufacturing, Facilities, Equipment, Building, Property, Hospitality, Restaurants, Churches, Fleet, School, Government, Gyms, Golf and more. If you work in an industry with valuable assets that need maintenance, a CMMS software could be beneficial to you.

Q: Does CMMS software work for small businesses as well as large corporations?

A: Although the implementations may be a little longer for larger companies, CMMS software is designed to work well for both small businesses and large corporations.

Q: What is the difference between a CMMS software and Facility Management software?

A: CMMS and FM software often mean the same thing, although some FM software packages have non-maintenance modules included. For example, FM software may have a space management module that a CMMS software package might not. Be careful on FM software or CMMS software that tries to do too much. Finding the right CMMS software is one of the key factors in a successful implementation.

1 Tampines North Drive 1 #04-27

T-Space Singapore 528559

T: +65 6686 0878

F: +65 6686 0085

E: ccsl@ccsl.com.sg

ffgfllf

ffgfllf